News

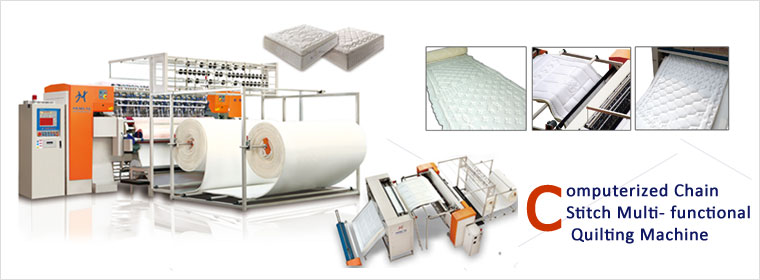

Computerized quilting machine related to introduce

From:HENGYE MACHINERY CO.,LTD OF DONGGUAN CITY AddTime:2014-7-7 5:03:55 PM Author:admin Hits:49

Key techniques of computer quilting control system and a linkage control technology as the saddle and roller, computer quilting machine adopts multi CPU parallel processing technology, data processing and transmission of quilting machine work, greatly improved the mechanical mode inverter traditional, solves the key technology of saddle control, roller control and main control quilting, realized the automation quilted product production process, has the functions of fault tolerance, strong function, automatic parking break overheat protection fault automatic detection and protection measures and system self diagnosis ability, also with the parameter setting, pattern of management of 5 major categories of more than 40 kinds of function, meet many quilting enterprises of various multi needle quilting machine, shuttle multi needle non bobbin quilting machine, multi needle quilting machine and single head rotary shuttle bobbin quilting machine for pressing demand for the new machine adaptation and transformation of the old machine and sewing machine.

Quilting machine control system overall technical design starting point high, better compatibility, strong anti-interference ability, optimize the design according to the specific requirements of the international design practice and computer quilting machine. Its technical characteristics are mainly embodied in the following aspects:

1), in the saddle and roller system control technology, according to the requirements of saddle or roller actual load, ball screw and belt transmission principle, quilting needle speed and stitch and sewing needle and plate phase and other parameters, the reasonable selection of saddle or roller drive motor, precise calculation of saddle or roller acceleration and material moving time, optimal design of saddle or roller driving instruction control curve, ensure the quality and yield of quilting quilting, improve the saddle or roller system control design technique, using the stepper motor to replace the AC servo motor drive to saddle, saddle rack and the roller system overall performance improvement.

2), in the spindle system control technology, according to the requirements of the actual load, belt transmission principle, quilting needle speed and quilting stitch and other parameters, the reasonable selection of spindle motor, spindle acceleration calculation, optimization design of spindle drive instruction speed control curve, ensure the quality and yield of quilting quilting, improve the overall design level development technique of spindle the system, using frequency converter with different.

3), the hardware structure and the whole system, according to the system performance and function, optimization design system circuit diagram, careful system design, system resistance to industrial environmental performance and stability design and system security design and other technical measures, strict control and the component derating design, reasonable selection of computer chips and various components and integrated circuit chip, in order to achieve the required function optimal unit price and highest reliability. Shielding, thermal design and correct wiring mode to realize the electromagnetic compatibility of industrial environment.

4), in the system control software, based on the complexity of software defect inherent error, environment, taken in the design of software is a series of preventive measures, and in the quilting process, monitoring the implementation of various actuators, misoperation prevent interference and other factors, improve the system's reliability.

Tel:+86-769-22264807 +86-769-22291362 Fax:+86-769-22663246 E-mail:hengye@hengyejixie.com Technical Support:Dongguan website construction